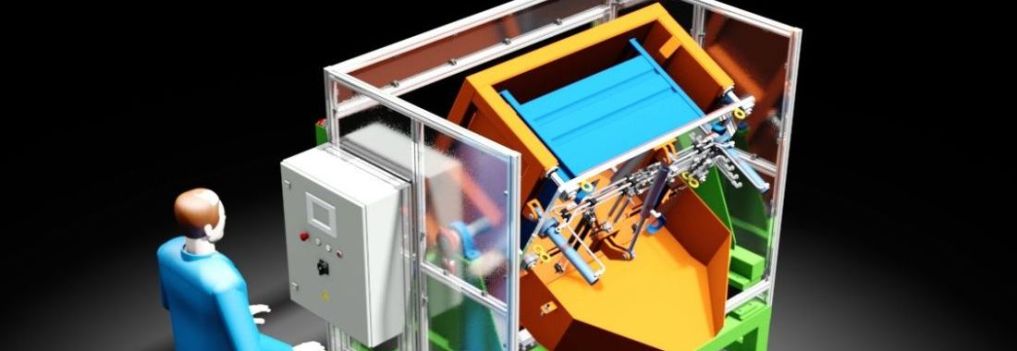

Empty the container with a tipping device or slide conveyor

As a manufacturer of vibration conveyors, we cover the entire spectrum of bulk material feeding.

This starts with our container emptying systems for emptying containers for subsequent further processing of the products in subsequent processes.

All emptying systems have one thing in common, 100% residual emptying depends on the container used and can usually not be guaranteed.

Our systems for container emptying at a glance:

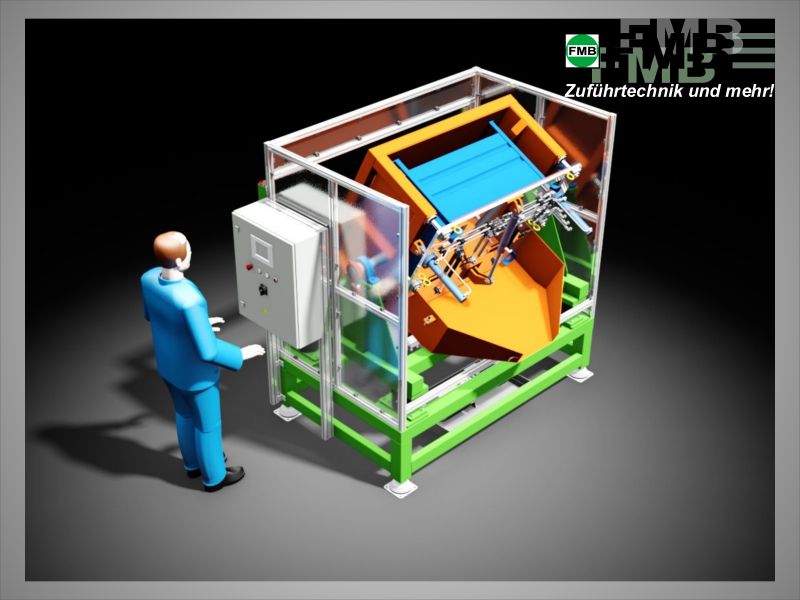

- Container tipping device BKG-1for various standard containers, tipping angle approx. 130°

- Container emptying system BGE-1for smooth-walled containers with hydraulic container closure and sliding conveyor technology

- Container emptying system BGE-2for smooth-walled containers with sliding conveyor technology and tracked tipping function

- Silo emptying system SES-1for silo container 2052 with central scissor lock

- Emptying platform EPL-1for special containers, e.g. containers with side wall opening

Container tipping device BKG-1 for various standard containers

Hydraulic tipper with a tipping angle of 130° for most applications.

It is emptied into an adequately dimensioned storage and dosing bunker, which can hold the complete filling volume of the container and meter it to the downstream conveyor system.

Container tipping devices are suitable for many types of containers and lattice boxes.

In combination with one of our storage and dosing bunkers, they can also be used as a dosing system for charging the furnace or for weighing and packaging.

Container emptying system BGE-1 for smooth-walled containers

with hydraulic container closure and sliding conveyor technology

With a conventional container tipping device, a container is pivoted overhead and the container contents are usually dumped in a separate storage bunker.

This has several disadvantages:

- Due to the drop from a tipping device into a storage bunker of partially Damage to the parts of several 100 mm can result from the parts falling out and hitting each other. The result is pseudo rejects to be avoided.

- The emptying process with a tipping device is very loud due to the drop height of the parts, depending on the nature and resonance of the workpieces, noise peaks> 120 dB (A) can occur.

- The storage and dosing bunker required in addition to the tipping device means that additional parking space and additional energy are required.

Container emptying system BGE - more than just a tipping device!

With the container emptying system BGE (container slide emptying), it is possible for the first time to convey the products to be fed in gently and quietly directly from the transport container with the help of the FMB slide conveyor technology, and to meter them directly into the downstream device, such as a vibratory bowl conveyor, without a storage bunker.

Containers with stiffening beads are only suitable to a limited extent, as they cannot be completely emptied.

As one of the leading manufacturers of sorting and feeding technology, in addition to our proven components such as high-performance vibratory spiral conveyors, spiral slide conveyors, large bunkers with slide conveyor technology and feed systems for workpieces that cannot be accumulated, we are once again showing an innovative feed solution as a result of decades of experience and know-how.

The container emptying system BGE is a novelty on the market and is offered exclusively by FMB!

Container emptying with sliding conveyor technology

A standard parts container is set down on the oscillating platform using a forklift. The container is closed from above with a hydraulically actuated cover, which is firmly clamped in the swivel frame and swiveled by at least 90° into the emptying position.

A bulkhead in the lid is now opened and the system is made to vibrate. The vibrations are directed in the system in such a way that the standard parts container is emptied using the sliding conveyor method.

The flow of parts at the transition to an on-site system technology is monitored. If there is no flow of parts, the container is swiveled back into the basic position and unlocked. The container can be changed.

No additional storage bunker required.

Advantages

Advantages of container sliding emptying:

-

Product protection

The material to be conveyed does not fall from a tipping device from a greater height into the storage and dosing bunker, but remains in the container. This avoids unnecessary drop heights and protects the products.

-

Noise reduction

The container emptying system is based on FMB sliding conveyor technology, i.e. the products are not thrown. The conventional micro-throwing principle with high noise generation and rough parts transport is NOT used here. The noise level in production can thus be reduced.

-

Variable dosage

A hydraulically opening bulkhead in the container cover allows the conveyed goods to be metered into the following devices regardless of the swivel angle. This prevents the parts from falling out like a conventional tipping device.

-

Energy saving

The drive in conjunction with our control electronics continuously records the loading status. The output of the vibratory drive is regulated depending on the load.

Full container = higher output, almost empty container = lower output.

Good and uniform dosing can be achieved through the detection.

-

Space savings

The container emptying system combines the container tipping device and the additional storage and dosing hopper. This means that less floor space is required compared to conventional devices.

More than just a tipping device!

Disadvantage

Basic problems when emptying the container:

-

Residual emptying

As with conventional container tipping devices, depending on the container type, 100% emptying cannot be guaranteed. Smooth wall containers are ideally used.

-

Limitations

Long, thin products; Molded rubber parts; Products that tend to build bridges; interlocking products; etc. cannot be fed.

Technical specifications

Technical specifications:

-

Container size

Standard container with dimensions 1.200 x 800 mm

-

Container weight

Maximum 1.200 kg

-

Swivel angle

Depending on the material to be conveyed up to 115 °, it can be set individually depending on the container type and application

-

Loading height

From approx 1.100 mm

-

Spout height

From approx 900 mm, depending on the set swivel angle

-

Vibratory drive

Low-frequency spring-mass drive with DC pulse magnet

-

Cylinder drive

Hydraulic for container clamping, swiveling and bulkhead opening

-

Control unit

Siemens S7

-

Electrical connection

230/400V 50 Hz

-

Noise level

Depending on the material to be conveyed, container type and emptying speed

Applications

Applications include in the following areas:

-

Ball bearings industry

-

Valve industry

-

Screw industry

-

Forging & forming industry

as well as in all other areas in which the material to be conveyed is to be metered out quietly and gently from the transport container.

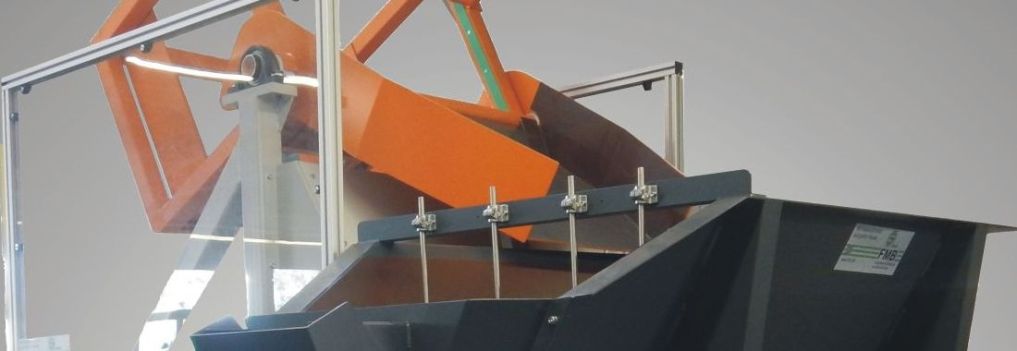

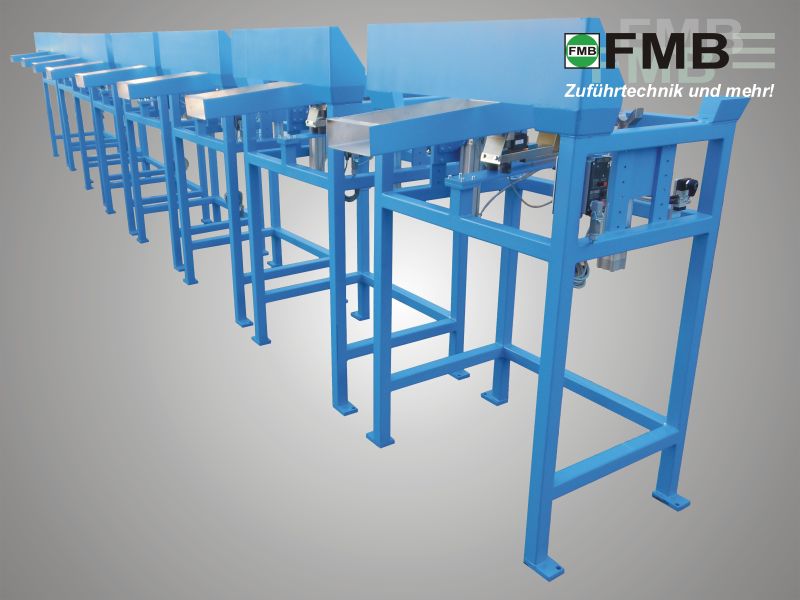

Container emptying system BGE-2 for smooth-walled containers

with sliding conveyor technology and tracked tipping function

Further development of the BGE-1 without a hydraulic container cover for larger and non-free-flowing workpieces.

As with the BGE-1, the emptying also takes place with our low-frequency vibratory drive, the flow of parts on the discharge chute is detected by sensors and the swivel angle is tracked step by step.

Containers with stiffening beads are only suitable to a limited extent, as they cannot be completely emptied.

Container emptying systems with sliding conveyor technology are offered exclusively by FMB!

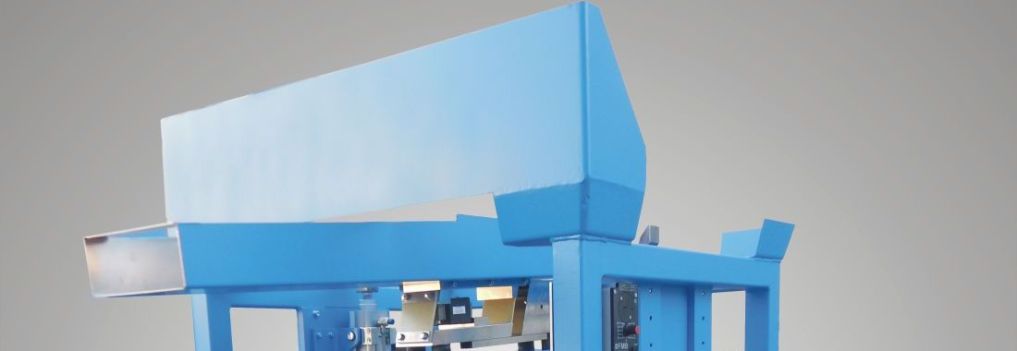

Silo emptying system SES-1 for silo container 2052

with pneumatic opening of the scissor lock and conveyor chute

Emptying of silo containers 2052 with central scissor closure for free-flowing workpieces.

The scissor lock of the silo container is opened via a hand lever valve with two pneumatic cylinders, so that the workpieces can be removed with the driven discharge chute and fed to the subsequent further processing in doses.

Emptying platform EPL-1 for special containers

with side wall opening and sliding conveyor technology

Containers with a side wall opening are fixed on a swing frame using power clamps. The side wall is now opened in a targeted manner and the container is slowly emptied by the oscillating drive.

With this system, there is no need for a tipping device or a storage bunker.

Solutions by FMB - your transport container becomes a bunker!