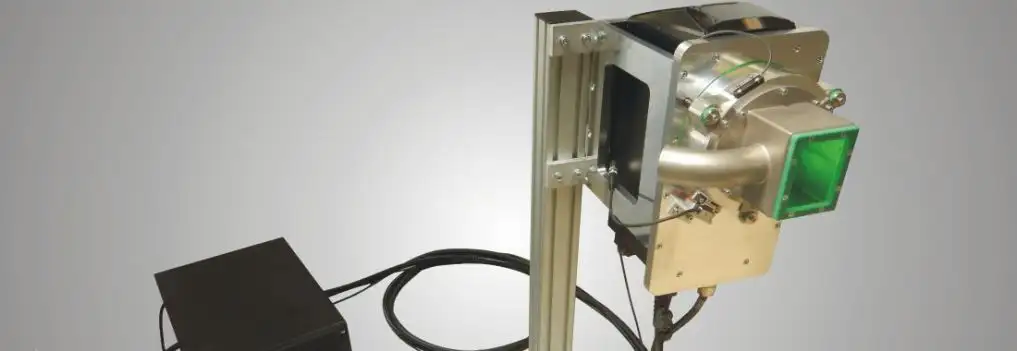

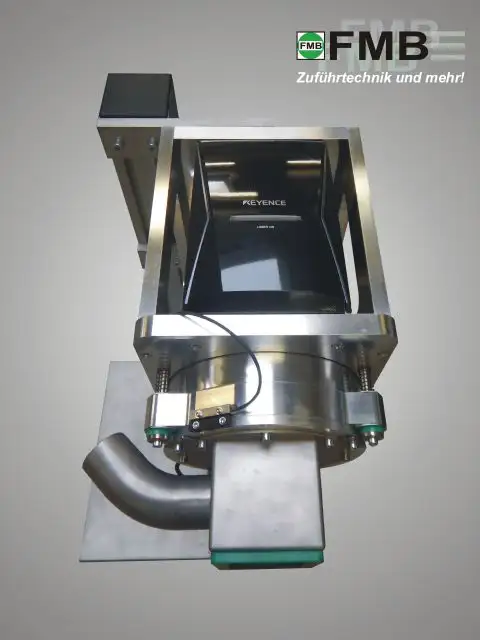

The safest laser protection system on the market in the smallest space

The laser protection system not only complies with laser class 1, but also ensures performance level e.

The Freehand Laser Safety laser protection system has been tested according to DIN EN ISO 13849 and meets the requirements of DIN EN 12254.

In contrast to other systems, Keyence lasers also switch off the laser diode when the protective contact is open.

Freehand Laser Safety for Keyence marking lasers is the compact and intrinsically safe laser protection system for your marking process for laser marking without a protective cabin!

This combination makes the system highly flexible and offers a wide range of possible applications.

Freehand Laser Safety

- Compact system for safe labeling of components

- Used for plastic and metal parts, among other things

- Stationary or mobile application options

- Inexpensive solution compared to complete housing

- Laser class 1 solution for lasers up to laser class 4

The use cases are diverse:

All types of labeling, whether plain text, codes or logos, are possible with this system.

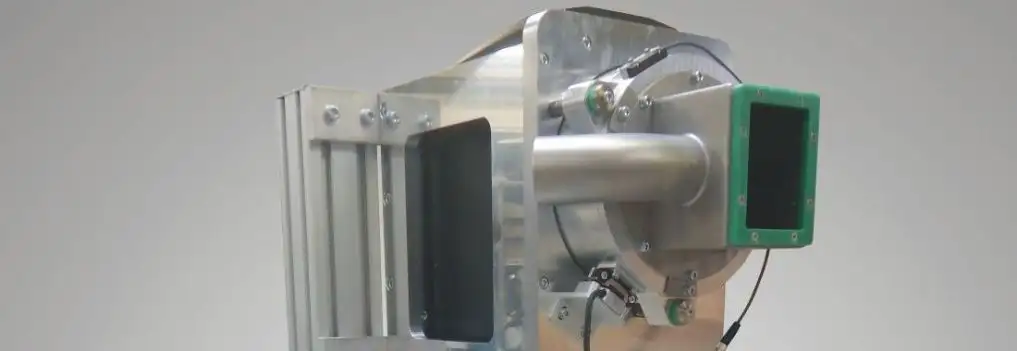

The marking of flat surfaces or molded parts is also no problem thanks to coded and exchangeable format parts.

Advantages:

Security

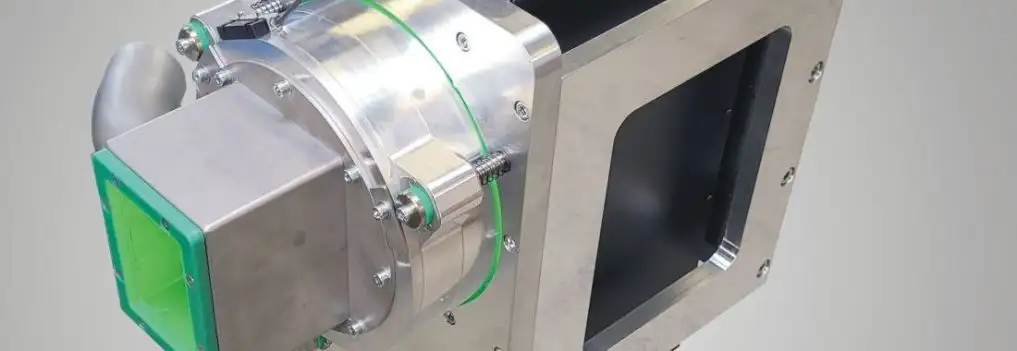

- Intrinsically safe due to 2-channel safety switch

- Switching off the laser diode when the protective circuit is open

- Additional mouthpiece query (optional with coding)

- Additional workpiece query optional

- Safe extraction of smoke and combustion residue directly at the mouthpiece

Flexibility

- Individual mouthpieces available for almost any workpiece contour

- Mouthpiece can be quickly changed (optionally with coding)

- Labeling field size from small DNC code up to 300 x 300 mm

- Application stationary or mobile

- Optional direct marking control by the laser without workpiece displacement possible

- Component marking from above or from the side

- Suction nozzle on the mouthpiece can be flexibly positioned

Savings

Costs:

- Cost-effective solution compared to complete housing

- Low follow-up costs by achieving Performance Level A

- No further closures necessary

Space:

- Minimal space requirement due to elimination of a laser protection cabin

Time:

- Easy integration of existing Keyence laser

- Low maintenance, resulting in minimal downtime

Process:

- Guide the product automatically (e.g. by a robot) in front of the format part, bring the format part into the end position and thus close the protective circuit

- Trigger laser process (ext. SPS)

- After completing the marking process, remove the product and thus automatically open the protective circuit again

Areas of application in the following sectors, among others:

metal processing - Plastic industry - Automotive industry - Mechanical engineering - Medical technology - and much more

Freehand Laser Safety - Make your marking laser safe!