Quality assurance for 100% control

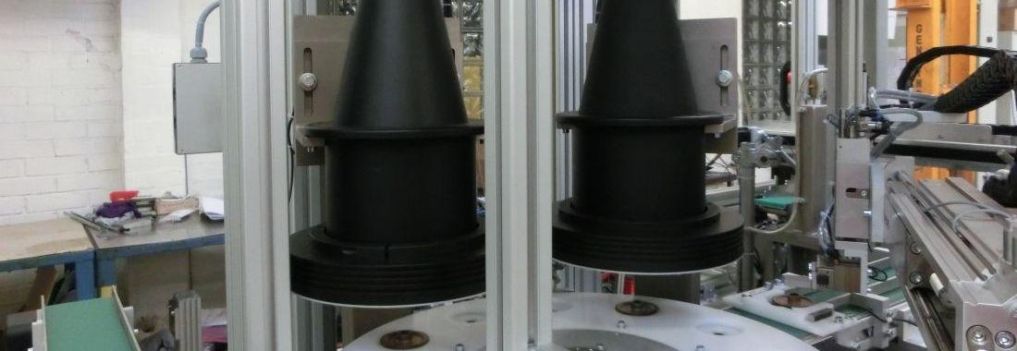

As a manufacturer of assembly systems and special machines, we are familiar with the requirement to subject workpieces to be supplied or fully assembled assemblies to a 100% inspection for quality assurance.

In order to be able to cover this task, we dealt with industrial image processing at a very early stage, and implemented the first solutions with it in the mid-1990s. Due to the growing demands on quality control, many other different test methods have been integrated into our machines and systems in the course of our company history.

We are a system integrator of various test technologies:

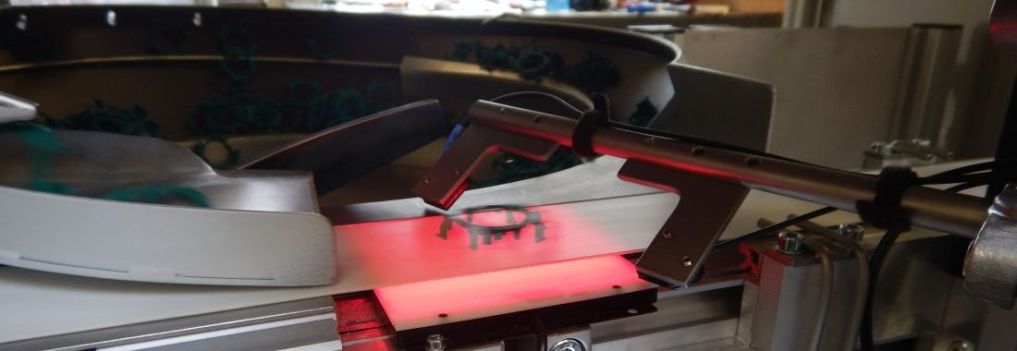

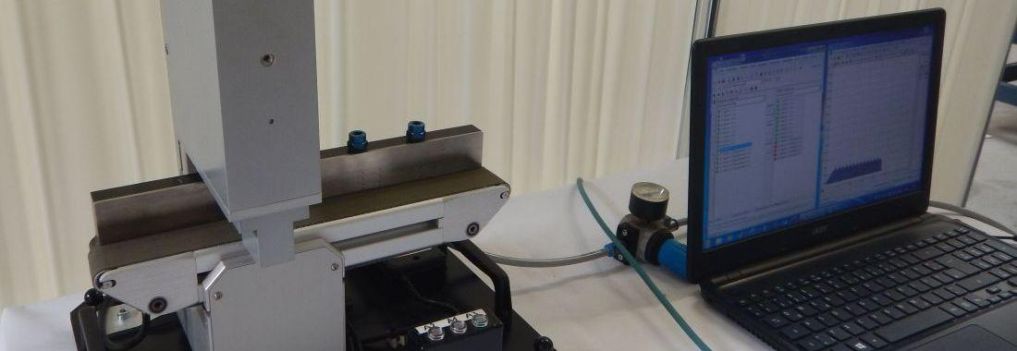

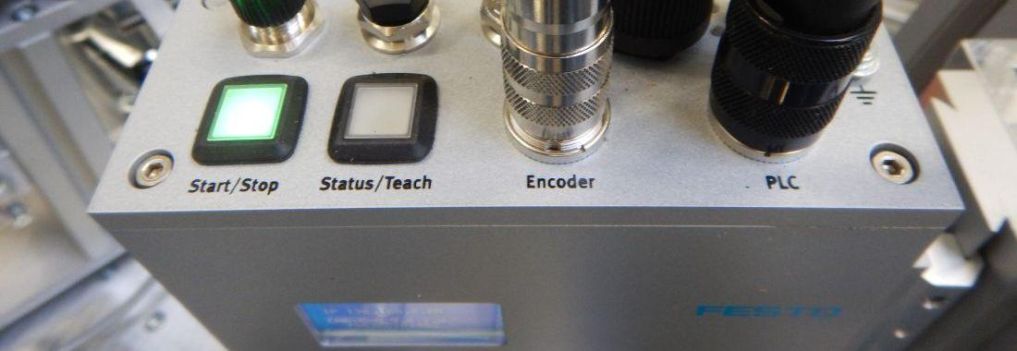

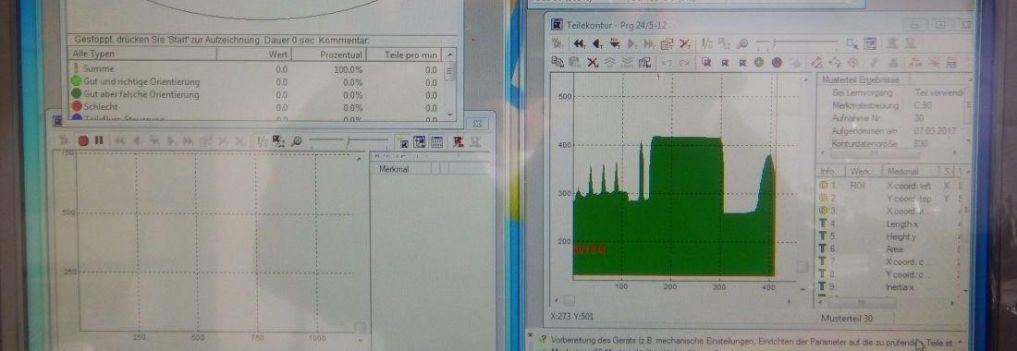

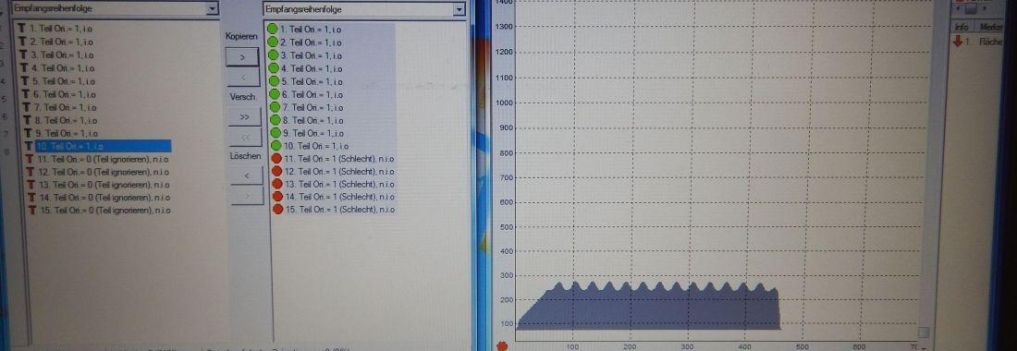

- Position and / or length control of workpieces with line scan cameras such as the Festo Checkbox Compact

- Position and / or completeness control with vision sensors (preferably Keyence, ifm, etc.)

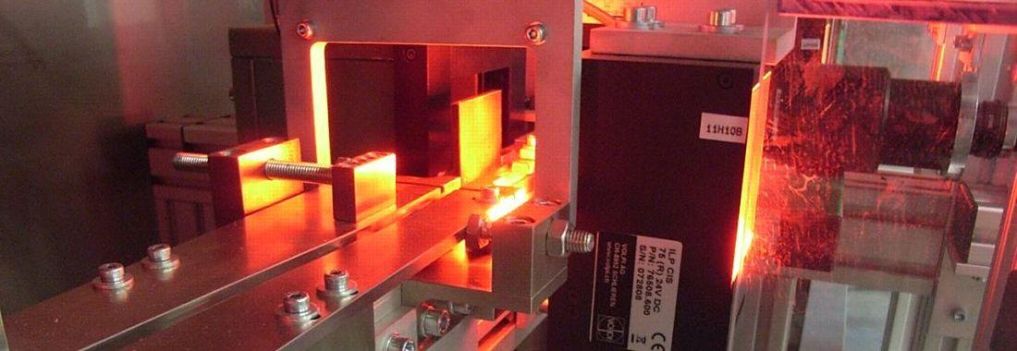

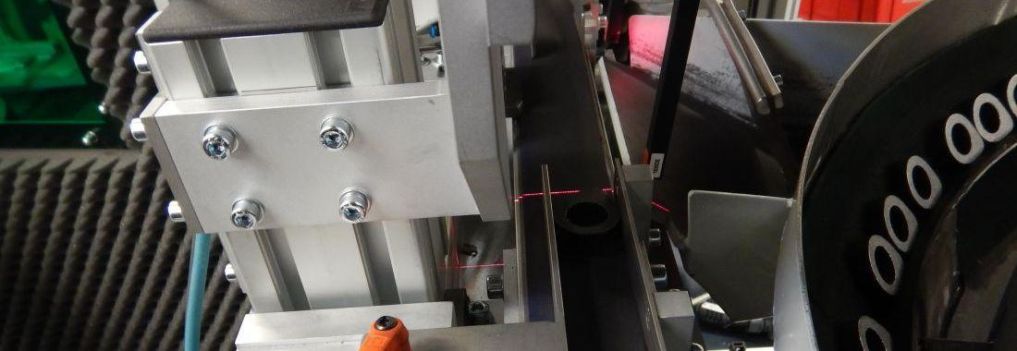

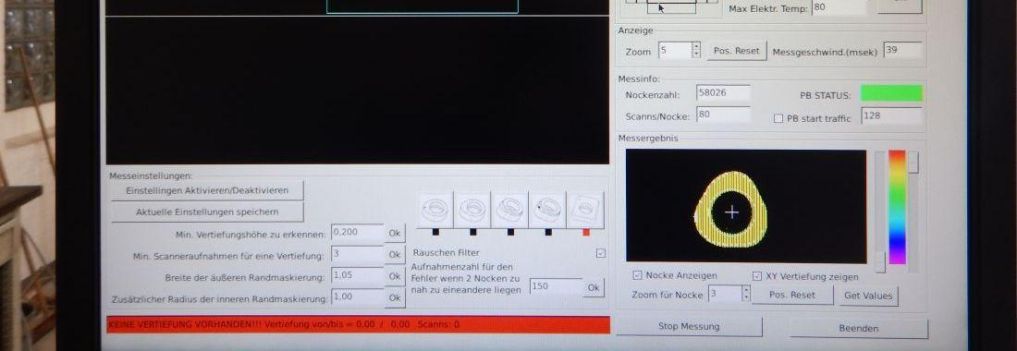

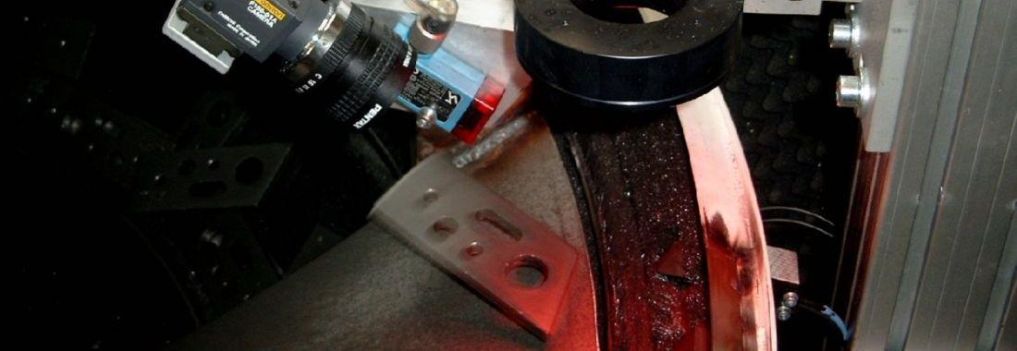

- Surface inspection with laser triangulation sensors

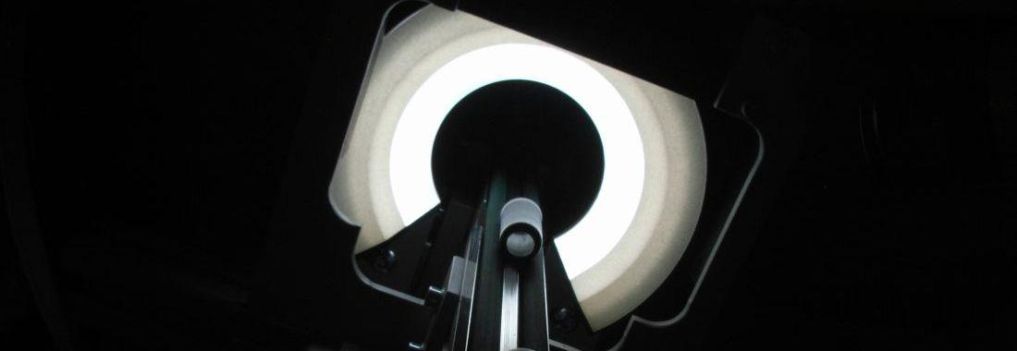

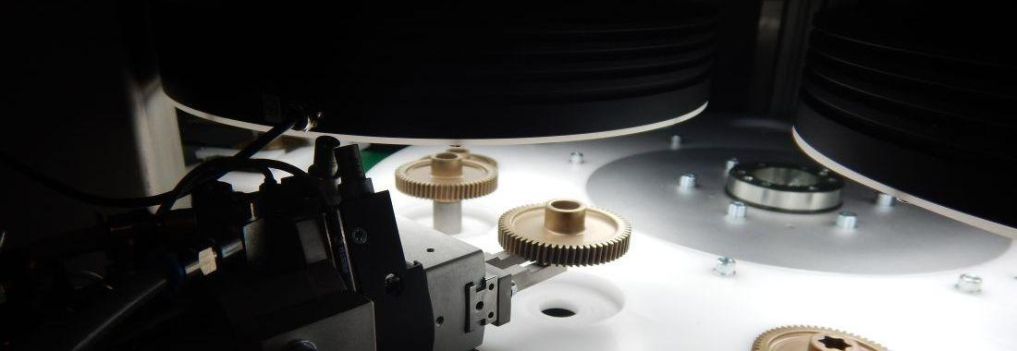

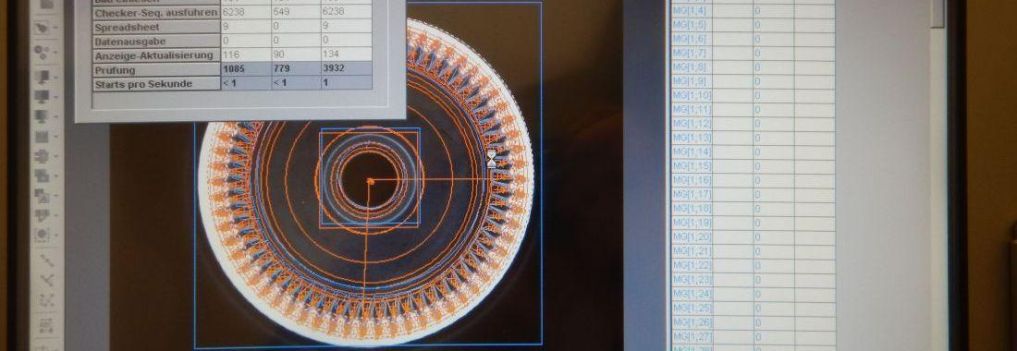

- Optical inspection with high-resolution image processing systems for component measurement or surface inspection

- Measuring systems for leak testing, flow or differential pressure measurement

- Force-displacement monitoring of joining processes

- Acoustic resonance analysis (sound test) for non-destructive component testing for cracks or structural defects

- Non-destructive hardness test using the Barkhausen method (Barkhausen noise analysis)

- Non-destructive material testing with eddy current testing to detect cracks or voids

- Functional test of completed assemblies

Technology solutions:

- Position detection of workpieces that cannot be mechanically sorted using a vibratory bowl conveyor

(partly possible as an integrated BV solution) - Checking quality features on workpieces such as surface control, completeness

- Recognize and select according to type characteristics

- Non-destructive testing of material properties such as cracks, structural or hardness defects

- Measuring physical quantities such as force / displacement / time