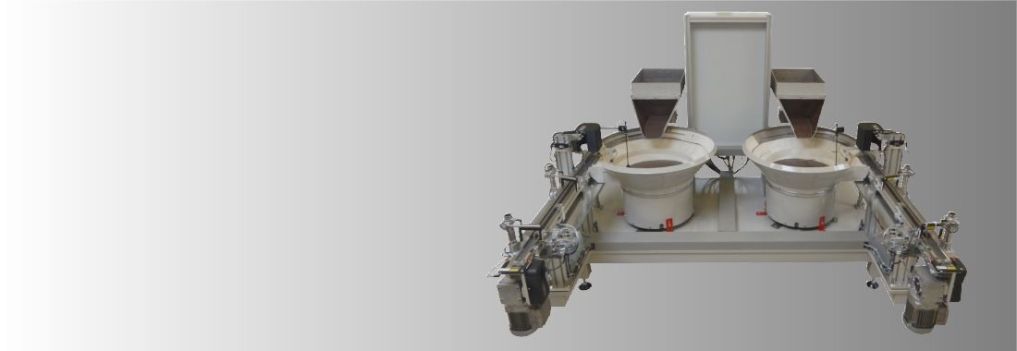

Workpieces with very sensitive surfaces and/or delicate edges have to be sorted and conveyed with care. The FMB range includes a low-frequency feeder which is capable of meeting precisely the requirements involved in such applications.

This equipment has been developed in-house by FMB and, for several decades now, has been successfully implemented in fields such as valve manufacture. FMB is the sole worldwide supplier of these machines to the major valve producing companies.

The video shows an example of a BGF-40 low-frequency feeder for conveying lamps.