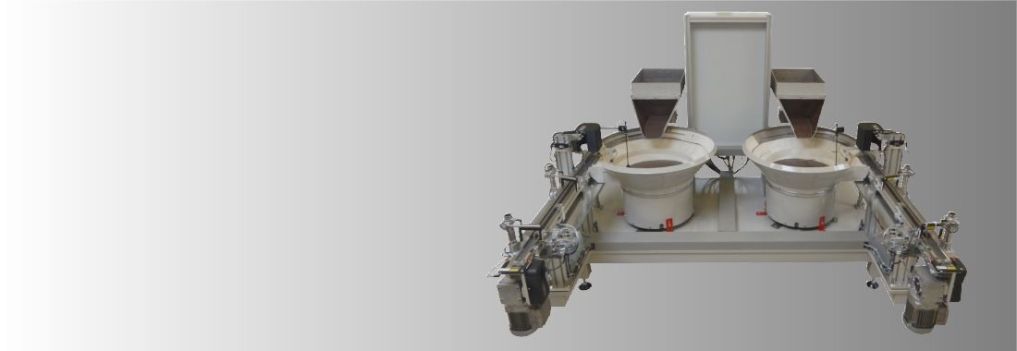

Feeding systems with components from our own development.

At FMB, we produce all components for feeder technology on our own premises. We assemble these high-quality components into extremely efficient feeder units with clearly defined intersections for integration into the customer’s existing production and assembly processes.

Feeder technology from FMB – reliable and efficient.

Our feeder systems are used in almost all areas of industry, and examples of where the quality and reliability of our feeder technology is appreciated by many satisfied customers can be found in the automotive industry, electrical industry, engineering, furniture, screw manufacture, stamping and forming technology, pharmaceuticals and medical technology.

Tailor-made feeder solutions in line with your requirements.

Feeder technology by FMB is just as individual as your requirements. Depending on the task in hand and the desired scope, our feeder units may comprise the following components:

- Containers and tipping devices

- Storage and metering hoppers

- Vibrating feeders (vibratory bowl feeders or low-frequency feeders) for sorting and correct positioning

- Noise-reducing covers

- Linear buffer sections (linear vibrating feeder or conveyor belt) for workpieces not suitable for accumulation

- Feeder systems for workpieces not suitable for accumulation

- Sorting and provisioning of the workpieces

- Blow-off device for injecting screws, pins, bolts and the like

- Handling devices (pneumatic, electromechanical or by means of robot)

Feeder technology for building inventory, sorting, singling out and provisioning.

We have the right feeder solution for your task as well.