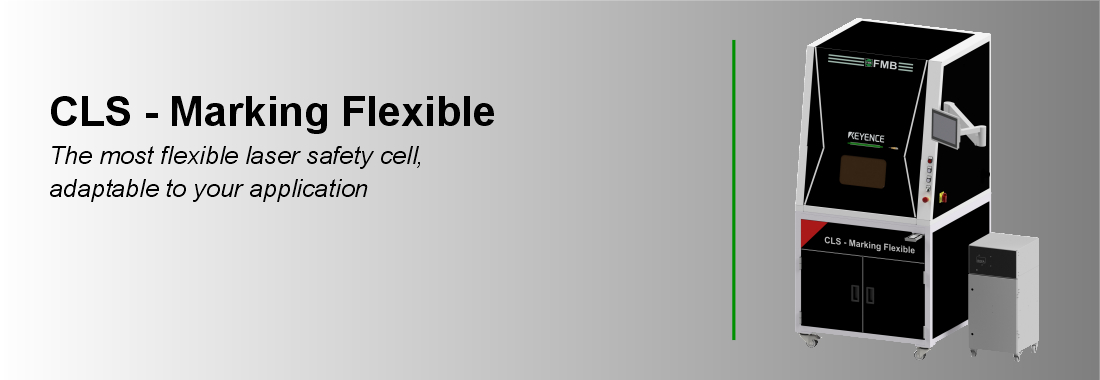

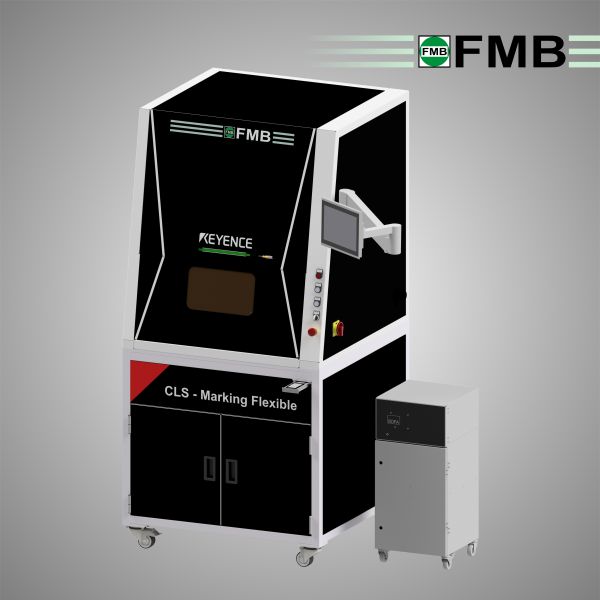

Closed laser protection cell, adaptable to your application

The CLS - Marking Flexible Laser Safety System from FMB combines the safety of a closed laser safety cabin with the flexibility of a freely adaptable system.

Despite the fixed enclosure, users enjoy maximum operating comfort and the ability to implement custom dimensions and individual adjustments.

The electric lifting door allows for convenient loading of the work area, while the integrated LED lighting ensures optimal visibility.

Laser Class 1 and Performance Level e protection guarantees the highest level of safety.

Flexibility and comfort despite cabin construction:

The work area and console frame can be customized to meet customer needs. Ergonomic solutions and easy handling are provided by electric lifting columns, either for individual workstations or automated processes.

The enclosed protective cabin with an electrically secured lifting door offers maximum safety and operator comfort.

Several extraction systems and accessories, including universal nozzles and product holders based on CAD data, are available.

The system offers the following advantages:

- Safe & comfortable - enclosed cabin with electric lift door

- Ergonomic - easy access to the work area

- Flexibly adaptable - all dimensions and options can be individually configured

- Automatable - integration into production lines via PLC possible

- Versatile - various extraction systems and accessories available

The most flexible laser protection cell, adaptable to your application.

Technical data:

- Console frame dimensions: 1,000 x 1,000 x 2,100 mm

- Working area: 600 x 400 x 400 mm

- Z-axis travel range: 400 mm (electric)

- Laser protection: Electrically secured lifting door, Laser Class 1, Performance Level e

- Marking laser: Keyence MD-X, MD-U, MD-F, ML-Z

- Marking area: 120 x 120 mm or 330 x 330 mm

- Suction connection: DN50 (side)

- Power supply: 230 V, 50 Hz

- Interior lighting: White LED

Equipment:

Standard equipment includes laser protection, smart control, aluminum T-slot plate, and laptop mount. Optional features include PLC control, panel PC, and various customized suction systems.

Typical areas of application:

- Series production with high ergonomic and safety requirements

- Laser marking of medium-sized components in closed systems

- Industries with particularly high safety and quality standards