The safety system for automated inline applications

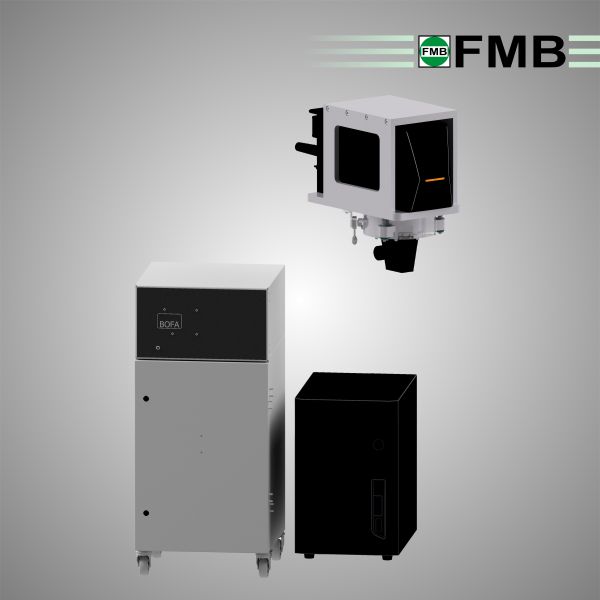

The Freehand Laser Safety laser protection system from FMB is the compact solution for anyone who wants to integrate laser marking efficiently and safely into their production processes – without the need for a complex safety cabin.

With Laser Class 1 protection and compliance with Performance Level e, the system meets the highest safety standards according to DIN EN ISO 13849-1 and DIN EN 12254.

Due to the innovative protective circuit monitoring, both the presence of the component and operational safety are reliably monitored.

This combines maximum flexibility with maximum protection.

Freedom of application:

Freehand Laser Safety enables automated inline marking without the need for large safety cabin. The work area remains flexible and open.

Safety and component presence are reliably guaranteed by a protective circuit sensor, making operation and robot integration particularly easy.

A specially developed labyrinth-shaped fresh air intake permanently keeps smoke away from the lens to ensure marking quality.

The system offers the following advantages:

-

- Compact and space-saving - no large laser safety cabin required

- Easy to integrate - ideal for robot integration and inline processes

- Efficient extraction - continuous extraction of fumes protects the lens and guarantees marking quality

- High flexibility - interchangeable nozzles for various components

- Safety-tested - Laser Class 1 and Performance Level e with 2-circuit protection level

This combination makes the system highly flexible and offers a wide range of possible applications.

Technical data:

- Housing dimensions: 420 x 230 x 450/580 mm (height depends on laser model)

- Laser protection: 2-circuit protection level, Laser Class 1, Performance Level e

- Marking laser: Compatible with Keyence MD-X, MD-U, MD-F, ML-Z

- Marking area: 120 x 120 mm or 330 x 330 mm (depending on laser model)

- Suction connection: DN40

Equipment:

The standard equipment includes laser safety and a flat nozzle for straight components.

The Freehand Laser Safety System can be retrofitted with various accessories, including universal extraction systems (Nano+ suction cup, large suction cup for PVC), customized nozzles, and flexible component detection with light sensors or initiators.

Typical areas of application:

- Inline marking in automated production lines

- Direct marking of components without a complex safety cabin

- Applications where space, flexibility, and cost are critical