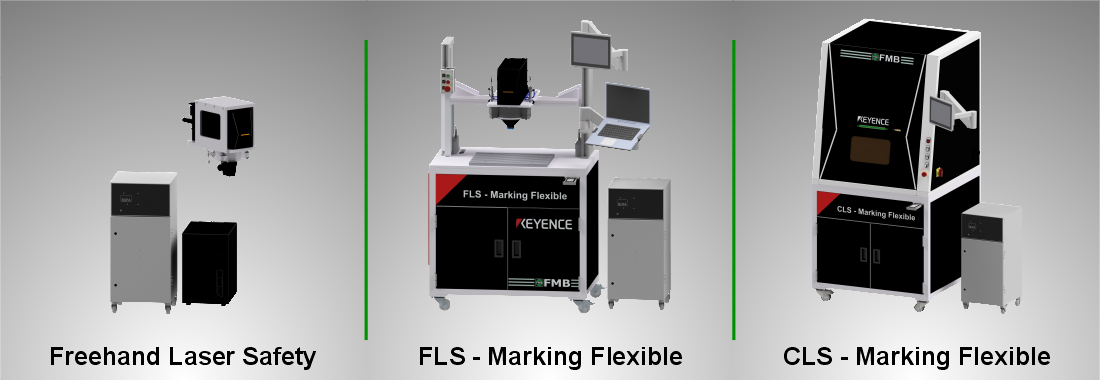

Laser marking without barriers, with Freehand Laser marking table

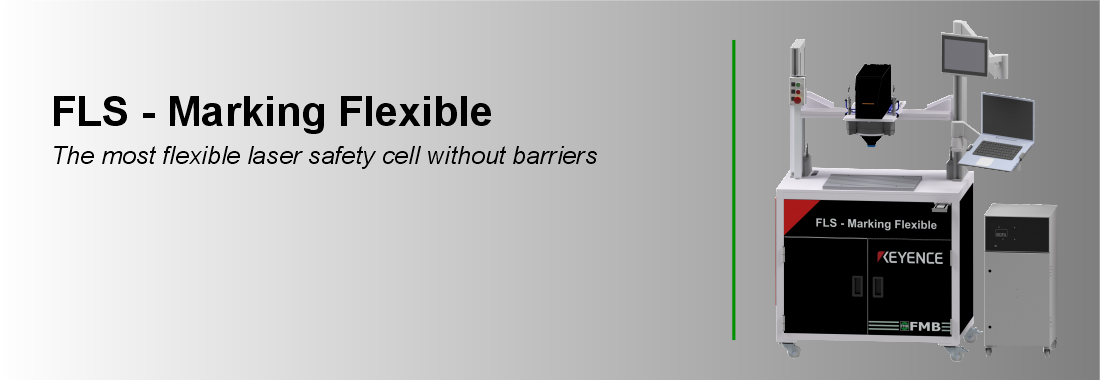

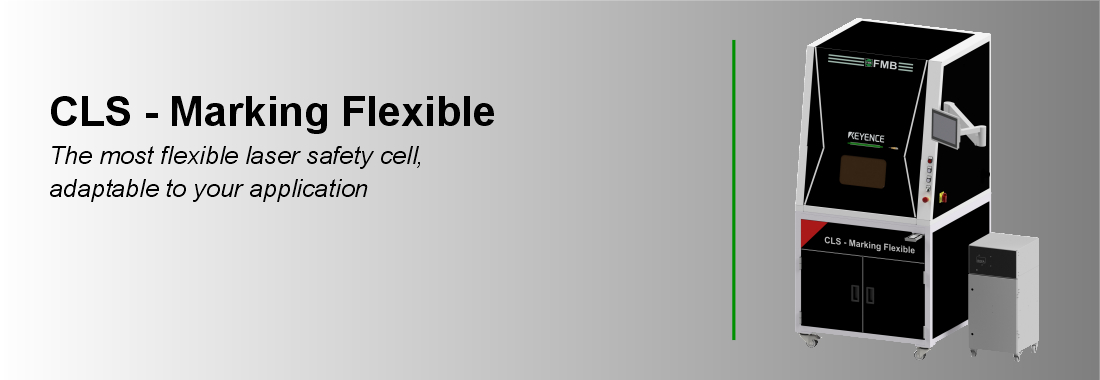

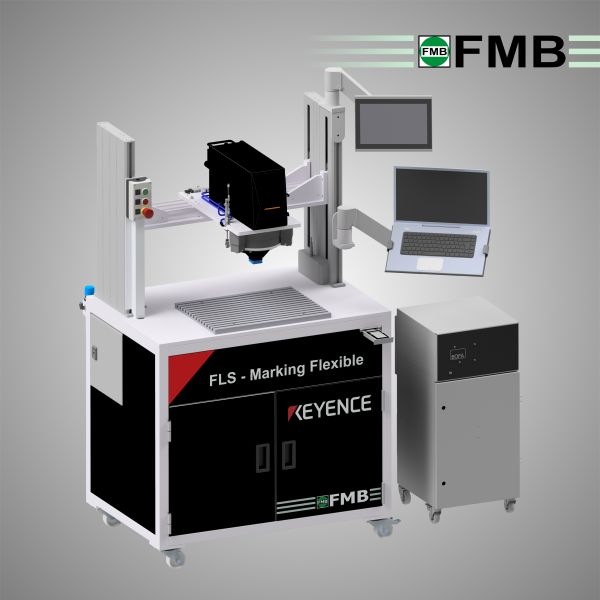

The FLS - Marking Flexible Laser Safety System from FMB is specifically designed for marking large and complex components and represents a particularly flexible solution for automation processes.

This is the most flexible laser safety cell without a complex safety cabin, with the Freehand Laser Safety integrated directly into a marking table.

As an open safety cell, the system offers maximum scalability and robustness – especially for complex assemblies and workpieces without a disturbing safety cabin. Its ease of handling results in reduced cycle times.

Can be individually integrated:

During development, the focus was on a freely scalable design that can be individually adapted to customer requirements. Ideal for projects with custom dimensions and varying component sizes.

Integration and control via robot connection enables fully automated and efficient series production. Safety circuit monitoring and component monitoring are also integrated for maximum process reliability.

Various extraction systems and accessory modules ensure universal use, even with special materials such as PVC.

The system offers the following advantages:

-

- Maximum flexibility - ideal for large or complex components

-

- Open system - no large laser safety cabin, Laser Class 1 and Performance Level e protection

- Automatable - easy integration into robot cells and production lines

- Cycle time - simplified handling results in reduced cycle times

- Customizable - work areas and console frame according to customer requirements

- Extraction options - different systems for different materials

The most flexible laser safety cell without barriers, Freehand Laser Safety integrated in a marking table.

Technical data:

- Console frame dimensions: 1,000 x 700 x 1,800 mm

- Working area: 600 x 400 x 400 mm

- Z-axis travel range: 400 mm (electrical)

- Laser protection: 2-circuit protection level, Laser Class 1, Performance Level e

- Marking lasers: Keyence MD-X, MD-U, MD-F, ML-Z

- Marking area: 120 x 120 mm or 330 x 330 mm

- Control options: Smart small control system, PLC (for automated processes)

- Suction connection: DN30

- Power supply: 230 V, 50 Hz

Equipment:

The standard equipment includes laser protection, smart control, a flat nozzle, and high-quality aluminum T-slot plates. Extensive accessories such as panel PCs, special suction systems, and customizable product holders are available.

Typical areas of application:

- Marking large assemblies in mechanical engineering and automotive

- Flexible workstation solutions in manufacturing