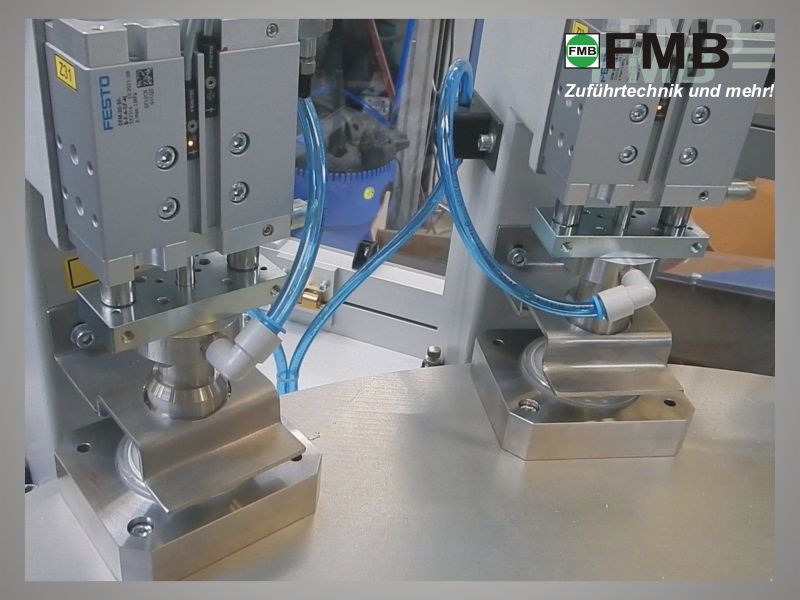

Assembly machine for bacterial and viral filters

Bacterial and viral filters for ventilators are manufactured with this fully automatic assembly line.

The filter assemblies are composed of the following individual parts:

- Housing patient side (2 types)

- 2 types of filter inserts (paper wrap or foam discs)

- filtrates (filter fleece)

- Housing device side (3 types)

- protective caps

A total of 3 variants with different constellations of the filter elements or housing designs to be used are manufactured with this system.

Problem case filter fleece

All individual parts are fed in with a storage bunker, spiral conveyor and linear vibratory feeder, complete with FMB feeding technology components.

A challenge was presented by the thin and non-dimensionally stable filter fleece, which cannot be fed into the assembly process in a conventional manner.

Once again, our proven "feed system for workpieces that cannot accumulate" was used, which we have expanded with an optical check for double or deformed filtrates.

With this system, slightly warped and non-accumulating workpieces can also be fed into the system.

Integrated testing technology, 100% control

The fully assembled filter assemblies are optionally subjected to a leak test and/or a flow test.

Depending on the type and requirements, the cycle time varies between 3.6 seconds. without leak test and 10.7 sec. with double leak test.

To the video of the assembly machine

Impressions:

All from a single source:

- Construction

- ProductionsSorting and feeding technology

- Assembly

- PLC control

- Commissioning and complete testing

- Installation and re-commissioning at the customer

-

100% FMB!